| �`�̴��ɧ��� |

| �o�@��Ҫ��ت��G²���`�̵��c���ƪ����O�ǡ]Thermodynamics�^�C |

| 1. ���� (Introduction) |

| �����s�����ƨӻ��A��o����O�Ǽƾڳ��O�D�`���n���C���O�ĥΪ�������k�ξa�� |

| �����ʤO�Ǥ�k�A���O�ǥi�H�b�ƥ��w���X���s���Ʃҥi��㦳���h�غc�y�A�H�γo�Ǻc�y��u |

| �����o�ͬ����ܡv�M�u�P�~�����Ҥ����v��]����í�w�ʽd��C�`�̺c�y���ƴN���\�h�s���Ƥ@ |

| �ˡA�B�b���u���O�ǥ��šv�����A�۷����A�]���N���O�ǦӨ��S�O����C���̪��W�B�ۥѯ� |

| (excess free energy) �ӦۤE�ӥi��ӷ��G |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| �H�W���@�س��i��o�ͦb�D�`�̺c�y�����Ƥ��A���`�̺c�y���Ʀ]���䰪�K�ɭ��A�Τ� |

| �פp�]�]���Z���u�^���ƾǦ�����P���O��סA�W���ҦC�X���o�Ǧ]�����|�ܱo����ۡC�E |

| �ئ]���ҳy�����W�B�ۥѯ�ä��۵��A�U�]���]���O�����W�ߵL�����A�����O�a�t�Τ��U�ئ]�� |

| ���۰ʼW��ո`�A�ӹF��N�����ۥѯ��`�M���̧ܳC�����A�C�Ҧp�G���F���C�ɭ���q�A�t�Τ� |

| �Y�i�ಣ�ͨ�í�w�ۡF���M�����ۥѯ�W���A����b�����h�O���C�F�W�B�ۥѯ�C |

| �o�g�峹�N�`�̺c�y���Ƥ����|���ӰQ�סG�]1�^��ۦh������ (polycrystalline single-phase |

| materials)�F�]2�^���(�Φh��)�h������ (polycrystalline two-[or multi-] phase materials)�F�]3�^��Ž�ƦX |

| ���� (filamentary composites)�F�M�]4�^�h�h���� (multilayered thin films)�C |

| ��ۦh�����ƪ��W�B�ۥѯ�D�n�Ӧ۴��ɻP���ɬۥ檺���u�C�]���Ҽ{�ɭ���(interfacial |

| energy)���]���N�̬����n�C��ۦh�����Ƴq�`�]�t��ؤ��|�ۤ������άۤ��X��(immiscible)���� |

| �A�����ɬO�W�L�j�p�ɳQ�٬��`�̬ۧ���(nanophase materials)�C����Ӭ۬O���ݮɡA�]�Q�٬��`�� |

| ���ɦX���A���M�o�˪��M���W���ä�����ܨ�ä��O��@�ۡC���@�۬O���ݡA�t�@�ۤ��O���ݮ� |

| �A�٤�����granular metal�� �]�H�Z�ص��G�_�Ǫ��Ϊk�A�q�S���L�C�^;��c�y�`�`�O�`�̪������� |

| �I�b�������|���������]�p�G�����^���A�Ӱ��N�U���ɤ��j�}�C��ۧ��ƪ��@�ө���S�x�O |

| ���ɭ����סA�]�ӼW�[�F�ۥѯ�óy�����ɼW�j�C�Ѭɭ��M��ۤ������ȫY�Ʈt���y�������O�] |

| �ܭ��n�C�H�W�����ƥi�Q�ήe���T�����`�̵��c���ơC�t�~�W�L��Ž�ƦX�������M���n����s�� |

| ���h�A�i�Q�����G�����`�̵��c���ơC�h�h�����O�@���`�̵��c���ơA�ѱ���H�n�k�s���A���� |

| �ڭ̷Q�n��s�u�ث����v (lengthscale effects) ���n���|�C�ҿפث����]�A������P���O��� |

| �C�h�h�����]�A�X�Ӭ�s��X���O (coherency stress) �P�ɭ����O�������C���M��ۦh�����Ƴq�`�O |

| �Ѭۤ����������۩Ҳզ��A�����P�h�h������̳��i�H���Ѥ@�Ǭ۲V�X���ƪ��d�ҡA�o�����Ʀb |

| �ƾǤW�D�`�����šA�x�s�F�j�q���ƾǯ�C���F�ɭ��~�A�`�̵��c���Ƥ]�i��t���W�G�M�`�j�q |

| ���ʳ��A�Ҧp�G�t�ƻP�ŤաC���F�h�h�������s�k���S�O�A�`�̵��c���Ʀh�ѶW�L�������s�Ӧ� |

| �C�]����ҳo�Ǥ@������W���ɪ����O�Ǥ]������C�H�W���쪺���e���|�b����ԭz�C���~���� |

| �]�|�Q�ר�w���M�ݩ�ʤO�ǦӤ��O���O�Ǣw�����`�̵��c���ƪ��D�`�w�C���ܪ��{�H�C�o�ز{ |

| �H�����ܯS�O����]�A�ӥB�b�����O�ǧP�_�ɫܭ��n�C���O�b�Q�ץD�n���e���e�A�ڭ̥����b�} |

| �Y���z���ɭ����O�Ǫ����[���C |

| 2. �ɭ����O�� (Thermodynamics of Interfaces) | |

| �b���[�ۥ��Ť��A�ɭ���b�j�h���p�����n�A�u�Pbulk Gibbs�ۥѯ���C���Y�Ϧb�DzΧ� | |

| �Ƥ��]�������s�{�O�Ѭɭ�����X�ʡA�Ҧp�G���ɦ��� (grain growth)�A�����ئ��� (Ostwald | |

| ripening)�C���W�L���ɻP�t�����K�ɭ����`�̵��c���ơA�u��bulk�ۥѯ�@���O�Ǥ��R��M�� | |

| ���T�CGibbs��ɭ����O�ǰ��L���������ɡA�H��S��C. Herring, W.W. Mullins, J.W. Cahn���H��T | |

| ����O�Ǧ��i�@�B���^�m�C�H�U�O�@�ӻP����᭱�z������²���`���C | |

| 2.1 �ɭ��i�O (Interfacial Tension) | |

| �ڭ����ߪ��D�n�O�T�餤���ɭ��A�Y���O��۶����ɭ��A�N�O�P�@�ج۪������ɶ����ɭ� | |

| �C���q�G�鶡�ɭ���²�污�p���_�Ӥ���e���C���M�u��ɭ����@�����e�� (a finite width) �A���w | |

| �q�@�ӵL�e��(sharp�A�i���s��)���ɭ��]�٬�Gibbs dividing surface�^�ΨӤ��R�ɭ���t�Ϊ������D | |

| �`���ΡF���]��۱q�����@����ɭ��A���ަb�c�y�W�P�ʽ�W����������C�N���ҫ��P�u��t�� | |

| ���ɭ�����A�o�{�ɭ��]�t�ƭӶW�B�q(excess

quantites) �C�S�O�O�C��쭱�n�����W�B�ۥѯ� |

|

| [���G���J/m2]�C�@�뻡�ӡA�W�B�q�P��ܤ��j�ɭ�����m�����F�o���D�Ш�Herring���峹�C�� | |

| �̥i��i�H���@�Ӧ�m�A�ϱo�o�W�B�q�P�ɭ������ס]���G���קY��ӥD�n���v���M�^�L���A | |

| �]�Ѧ���m�өw�q�W�B�q�C | |

| �榨���y��۪� |

|

| ������ (a strtched membrane)�A�� |

|

| �O�ߤ@�ɭ��W���O�A�q�`�Q�٬������i�O (surface tension) �άɭ��i�O (interfacial tension) [���G��� | |

| N/m]�C����Ӭy��۹F�쥭�ŮɡA�@�Φb�ɭ��W�� |

|

| �������OP |

|

| (1) |

|

| �䤤��r1�Pr2�O�H |

|

| r ���y�� |

|

| |

(2) |

�H�U�ڭ̶}�l�Ҽ{Gibbs�O�p��B�z�P���R�T�餤���ɭ������G�]2.2�`�^�h����T�骺�W�B�ۥ� |

|

| ��F�]2.3�`�^�ɭ����O�F�M�]2.4�`�^�ƾǥ��šC���ۧڭ̰Q�PGibbs���P�����R�覡�G�]2.5�` | |

| �^���ܬɭ��ҫ� (a diffuse interface model)�F�M�]2.6�`�^�ɭ��ۼҫ� (an interface phase model)�C | |

| 2.2 �`�̴��ɩT�骺�W�B�ۥѯ� | |

| (Excess Free Energy of a Nanocrystalline Solid) | |

| �@�Ӭۦb�h���ɪ��ۥѯ�n��洹���C�h�X�Ӫ��ۥѯ�O�Ѩ䤤���ʳ�(�Ҧp����)�ҾɭP�A | |

| �Y�O�`�̴��T��h�i�H��²�檺���X�]��4.1�`�^�C�D�n�ʳ��N�O���ɥ����A���`���n�Pd^(-1)�] | |

| d�����ɪ��|�^����ҡC���ɭ��ۥ檺���u�]�H��²��Gb��u�^�i��㦳�S�O���c�y�A�]�i��W | |

| �[�W�B�ۥѯ�F���`���Pd^(-2)����ҡC��Gb��u�b���ɥ樤(grain vertices)�|�ۥ�A�o�ǥ��I�] | |

| �i��W�[�ۥѯ�F��ƥرK�|�Pd-3����ҡC����ݨӡA�����n���W�B�ۥѯ�Gexcess���H�U | |

| �����w | |

(3) |

|

| �䤤�� |

|

| �����ת�Gb��u�ۥѯ�A�� |

|

| ���������i�H�����C�H�W�ﴹ�ɮ��������R���O�ھ�Gibbs����k�A�N�W�B�ۥѯ���t��z�Q�W | |

| �L��n���ʳ��C�o�˪��B�z�A�u�����W�B�ۥѯ�]�Υ����ȡ^�����T�w�q�åB�Pd�L���~��C[�H | |

| �Z�ص��G�]�N�O�L�״��ɤj�p�A��쭱�n�����ɯ�B�����ת�Gb��u��B�ӧO�����I�ೣ�n�O | |

| �w�ȡC�o�b��ڤW�ܥi��O�����T���C] �J�M�ڭ̪��D�U���ɦb�ʽ�W���t���i�H�ܤj�A�o�ؤ� | |

| �����G�O����ۥѯ�C�ҥH�b���o���P�ɮ|�j�p���˥��ɡ]�s�{��M�|���P�^�A�]�n�`�N�� | |

| �������ɺ������G�O�_�@�ˡC��i�@�B�A�Y�ϴ��ɺ������G�ۦP�A�p�G�ʳ����e�Pd�۷��A�o | |

| �ؤ�k�]�|���ѡC���ɧڭ̴N�ݭn���ܴ��ɪ��B�z�覡�F�]��2.5�`�^�C | |

| �h�h�����O�Ѩ�ۥ椬�|�m�Ӧ��C��۶����ɭ��ʽ�`�i�H���@�P�h�h�����ƶZ��

|

|

| �C�]���䤤�õL��u�Υ��I�A�Ѭɭ����ͪ������n���W�B�ۥѯ�w | |

(4) |

|

| 2.3 �ɭ����O (Interfacial Stress) | |

| �ڭ̤@��i�H�Ĩ�������k�A�Υi�f���\�ϩT�骺�����W�j�C�@�جO�θѲz�]�ζ�ʬy�� | |

| �^��}�T��гy�X�s�������F�ҥ[���\�N�٬������]�ɭ��^�ۥѯ� |

|

| energy)�C�t�@�ؤ�k�A�I�O�N�����u�ʪ��Ԧ��H�W�[���n�F�Ұ����\�h�P�����]�ɭ��^���Ofij�� | |

| ���C�b�Ĥ@�ر��ΡA�s��l�Q�a������A�ҥH�������ʽ�S�ܡC�ĤG�ر��ΡA�S���s��l�Q�a�� | |

| �����A�Ӫ������ʽ�w���ܡC�`���������O�M�����ۥѯ�P�u������ |

|

| |

(5) |

| �䤤�� |

|

| �q�@�ӼƭȬ�f�����V�ʪ������O�C���b�y�鶡���ɭ��A���|���u�ʩԦ��A����

|

|

| �A�]��f�P�����ۥѯ� |

|

| �C�b���ݪ��ۥѪ����W���ɭ����O���D�A�]���@�ǹ�����q�P�p��(���^�U�峹[8])�C���G��ܦ� | |

| �Ѫ������ɭ����O�P�ɭ��ۥѯ�j�p�ݩ�P�@�ƶq�šA�æb�p�ɩT�����ɧΦ����Y���O�C��@ | |

| �ӳB�b�y��� |

|

| �w | |

| |

(6) |

| �b��өT�餤���ɭ��A�Y�ϰ��]�ɭ��ʽ謰���V�]�ɭ����A�P�ɭ������ɪ���V�L���^�A�䤤�] | |

| ���T�جɭ��O�G�ɭ��ۥѯ� |

|

| �T�骺�u�ʩԦ����������O�C�b�T�餤�����O�h�a��өT�骺�u�ʼҼƦөw�w | |

| |

(7) |

| �䤤 r0 �O�b�T���� |

|

| �u�ʼҼơA |

|

| 2.4 �s���ɭ��W���ƾǥ��� (Chemical Equilibrium at a Curved Interface) | |

| �s���ɭ��ﷻ�ѫת��v�T�ܤj�C�Ҽ{�@�ӯS�������p�A�t�榨��A�� |

|

| ��t�h�������y�� |

|

| �FA�b |

|

(8) |

|

| �䤤 |

|

| ���ܤF�ɭ������n�A�]�ӧ��ܤF�t�Ϊ��ۥѯ�C�P�ɦb�P��y�餤A���ƾǶդ]��ۧ��ܡG | |

| |

(9) |

| �b�����ɭ��F�쥭�ŮɡA��Ӭۤ������O�۵��A�ƾǶդ]�۵��C�i�O���ɭ��O�����ɡA�ھ� | |

| (8),(9)�⦡�A���Ȩ�ۤ������O���P�A�s�ƾǶդ]���@�ˡG | |

| |

(10a) |

| |

(10b) |

| �p�G��Ӭ۳��O�y��Af �|���� |

|

| |

|

| �ܤƥi�H���ܦ��G | |

| |

(11) |

| �䤤R�O����`�ơCA���Ѧb |

|

| �p�G��¶���O�T��A�h�ƾǥ��Ū����R�|�D�`�����C�䤤�� |

|

| �������ƾǶեi�ण��o���C�Y�K�p���A�ɭ��ۥѯ� |

|

| �D�n�^���v�T�C | |

| ���F�W���ҰQ�ת��A�ɭ��W��l�b����ɪ��ƾǥ��šC�b�h�����t�Ϊ��ɭ��W�A���Ůɥi | |

| ��|�o�ͦ��������ơC�]�N�O���A���Ǧ����|�ɦV��l���b�ɭ��W�A���ǫh�|�ɦV������ɭ��C | |

| �o�ؤ��Ƨ@�μv�T�F�ɭ��ۥѯ�A�ӥB�P�ūצ����C����ä��Q�צ������A������Ш�[9]�C | |

| ���סG�u�ۻP�۶������šv�M�u�ƾǦ����������šv�A�`�`�O�u�P�ɭ��ۥѯ�����C�T�� | |

| ���������O���A�A�h�O�u�P�ɭ����Of�����C | |

| 2.5 ���ܬɭ� (Diffuse Interfaces) | |

| �H�W���Q�׳��N�ɭ������@��sharp dividing surface�C�u�n�ɭ����u�����ܵ{�סA�۹����� | |

| ���L�c�y�ثרӻ��ܤp�A�o�˪�²�ƳB�z����O�ܦ��Ϊ��ҫ��CCahn and Hilliard [10] ���L�s���� | |

| �����ܬɭ����@��ʴy�z�C�L�̦Ҽ{�����ʯ¶q(intensive scalar)�ʽ�]�Ҧp�G�Y�@�������K�� | |

| �ο@�ס^�A�b�B���Ӧ��ʽ�۲��ϰ춡�ɭ��W�������ܤơC�o�̶ȰQ���������T���餤A���� | |

| �����դ��qCA�ʽ�A�B���]CA�u�O�@�ӹ�@���Ŷ��Ѽ�x����ơCCahn and Hilliard���ɥX�t�Τ� | |

| �����n��local Helmholtz�ۥѯ�f�A���ȻP���������������A�]�P������������שM�ɨ�Ʀ� | |

| ���A�Y�u����Ĥ@����������G�G | |

|

(12) |

| �䤤 f0(c) �O�@�Ө���դ��q c �����èt�Ϊ������n�ۥѯ�F

|

|

| energy coefficient)�C�b��Ӥ�������(immiscible regions)�����ɭ��W�A��ɭ��e�h�Ѩ�Ӧ]���ۤ� | |

| �v���ӨM�w�G�u��p������סv�P�u��p�㦳�����Ŧ������誺��n�v�C�L�̹w���ɭ����e�O | |

| �ӷūת���ơA�ūV���h�V�u���ܡv�A���챵��@�{���I�h�|�o�����ͩ�L���j�C��ׯ�q�Y | |

| �ƫh�i�ѩT����ҫ��o�X�C�p���G�ɦV��ۤ����]�Y�ɦV��Φ��ɭ��^�A�h�Y�Ƭ����F�p�t�ζ� | |

| �V��ƾdzW�h����(chemical ordering)�A�h�Y�Ƭ��t�C�ۤ����t�Τ�����ׯ�q�������㪺�������` | |

| �ۥѯ�C�ܩ���X�����v�T�A�Ш�6.1�`�C | |

| 2.6 �ɭ��� (Interfacial Phases) | |

| ���P��2.1��2.3�`���t�@�سB�z�A�O�N�ɭ��Q���t�~�@�Ӧ����éʽ誺�ۡC���M�b�Y�DZ��p | |

| ���ΡA�����夣�A�Q�סC�Ա��Ш�Guggenheim [11]�CFigure 1�ܷN��ø�X��b�ɭ�����ʽ��ܤƪ� | |

| �U�ؼҫ��C | |

|

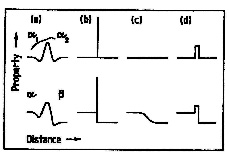

Figure 1. (a) �@�ӫܸرi����ɭ�����ʽ�ΰѼ��ܤƥܷN�ϡA�W�����@���ɡ]����P�ۡ^�A�U���h�����P�ۤ���ɡC (b) Gibbs���ɭ��ҫ��A�N���餺�������ʽ觡�@�A�ӱN�W�B�ʽ趰���b�e���s���ɭ�spike�W�C (c) ���ܬɭ��ҫ��A���D������ɪ��ѼƩw�����P�A���M�����������ɡC (d) �ɭ��ۼҫ��A�N�W�B�ʽ趰���b�@�����e�ת����ðϰ줤�C |

| �椸�C |

�椸�K |

�椸�E |